A hermetically sealed connector is designed to deal with extreme conditions. That is the reason it is often used for military or industrial purposes. Astronauts and scuba divers may rely on these connectors to provide the best possible connection in the most unlikely places. Lives may literally depend on the strength of a seal, so that is why it is essential to choose the right connector.

Types of Hermetic Connectors

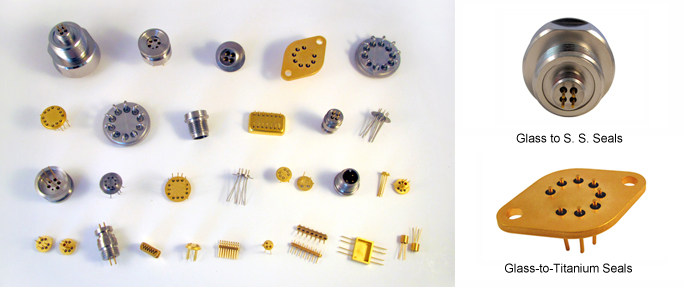

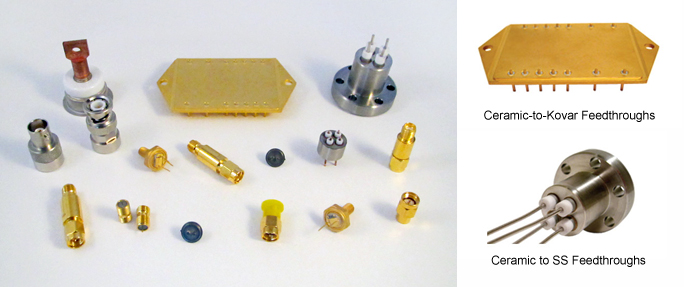

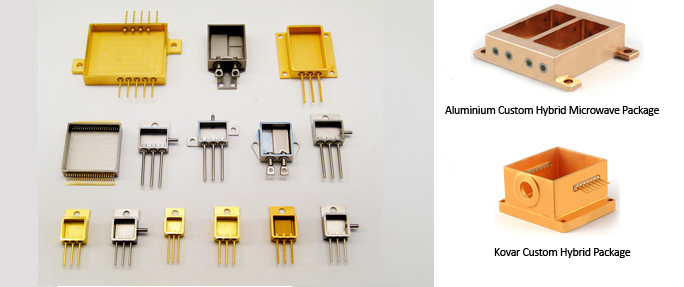

The kind of hermetically sealed connector you choose most likely depends on how secure you need the connection to be and whether you want a custom connector. A popular kind is a glass to metal connector that is made out of molten glass and is combined with metals. Ceramic to metal types are also available, and they require more time to produce, but can be custom-designed. Whatever material you select, the connector should provide the strong connection you need for any job.

Under What Conditions Can Hermetic Connectors Hold Up?

A hermetically sealed connector can hold up to extreme temperatures and below zero conditions. They should be able to withstand conditions in a spaceship and zero gravity or areas of high pressure. The connectors can also work in a vacuum and at the bottom of the sea. Simply put, hermetic connectors can handle just about anything.