Engineers are often tasked with the job of creating seals around ceramic feedthroughs. Sometimes the seal is as simple as an epoxy or glue. For those situations that require a stronger seal, a mechanical or glass seal is necessary. The ceramic feedthrough is often a vital part of the seal and is used in situations where the highest performance is expected.

The Advantages of Ceramic vs. Glass

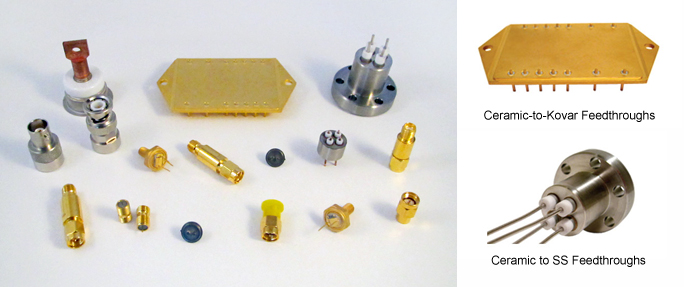

Ceramic feedthroughs offer some important benefits, superior resistance to both mechanical and thermal shock, an ability to resist corrosion, and protection from leaks. Glass can resist the effects of temperature changes, fluctuating pressure, and variations in humidity. Ceramic, however, provides better performance. Ceramic-to-metal applications require complicated engineering and typically comes at a higher cost.

Who Uses Ceramic Feedthroughs?

There are some industries that require the high level of performance delivered by ceramic feedthroughs. These industries include the aerospace market, medical implant device manufacturers, and industries using high voltage or current laser applications.

Look for Providers of Great Quality Feedthroughs

Manufacturers can protect the components of the glass and ceramic feedthroughs by working with internally-sourced ceramics and other materials. It’s important to learn how to recognize the best types of hermetic seals and feedthroughs; working with knowledgeable manufacturers can help. You can protect the integrity of your project by choosing top-quality ceramic feedthroughs from reputable providers.