Lithium battery seals are critical components in many types of batteries. From medical equipment to weapons control systems, these batteries must serve as essential power sources. With durability, dependability and power output as important performance indicators, batteries’ seals should adequately support their functionality. In this short guide, you’ll learn about the advantages of battery seals constructed from lithium.

Benefits of Lithium Battery Seals

Battery end seals serve an important function: keeping a battery’s electrolyte and internal components inside its housing. A battery end seal ensures that its power cell stays reliable, functional and safe for ongoing use. Battery seals come in a wide range of materials:

- Titanium alloys

- Stainless steel

- Aluminum

- Steel alloys

- Lithium

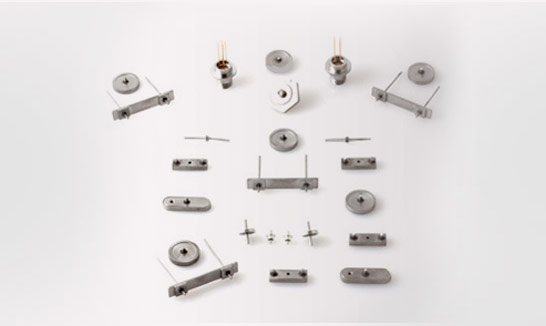

Complete Hermetics manufactures several lithium battery glass-to-metal sealed lid products. Glass-to-metal seals offer unique advantages. Their construction creates a reliable high-quality seal that withstands exposure to harsh conditions, including temperatures between -40°C and +150°C. They also resist humidity extremes, electrochemical corrosion, pressure variation and high-voltage electrical currents. Lithium seals offer excellent performance in all these areas, along with offering a longer shelf life.

Your Source for Lithium Battery Seals

Complete Hermetics custom crafts glass-to-metal and ceramic-to-metal seals, as well as hermetic seals and feedthroughs. Through engineering and manufacturing excellence, we deliver superior-grade products meeting strict quality standards. Request an online quote now or call us at (714) 265-1238.