Whether in medical, military, aeronautic or any myriad of settings, failure of hermetic headers can have catastrophic outcomes. How can you ensure that your hermetic packages are up to the challenge of your unique hermeticity needs? Here are three ideas to ensure your devices won’t fail.

Hermeticity Testing

Hermeticity testing primarily involves either fine leak testing or gross leak testing. The former examines hermetic packages for defects that can lead to leakage, while the latter focuses on damage that can cause gross package leakage. Periodic testing is a good way to detect faults before a major incident.

Choose the Right Seal

The proper hermetic seals are key to preventing leakage. Glass to metal seals might be best for pressure-tight windows, while glass to glass might be better for glass tube components. When choosing hermetic headers and packages, consider the material you are sealing.

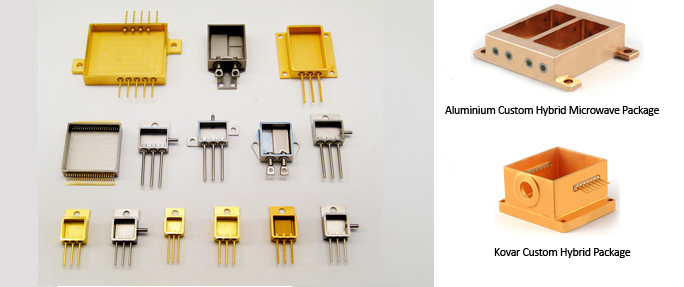

Pick an Experienced Manufacturer

The market for hermetic headers is a broad one and it can be difficult to know which manufacturers are ideal. A good rule of thumb is to find a manufacturer specializing in more than one type or market of hermetics. Choose a company offers a good mix of seal types with hermetic packages designed for various industries. Finally, look for one with a trusted name and years of experience to ensure hermetics you can depend on.