Battery end seals play important roles in battery life, functionality and power delivery. They create tight seals that stop any unusual loss of electrical energy. With missing or damaged end seals, batteries lose power faster than usual and their typical lifespans decrease.

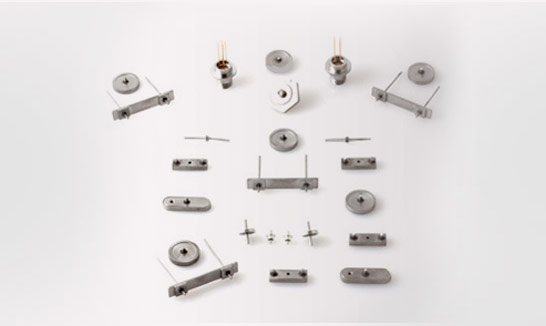

Lithium Battery Sealed Lids

Hermetic seal technology is key with lithium battery sealed lids. Glass-to-metal sealing techniques require both the glass and the metal to have similar thermal expansion properties to ensure a solid seal when the pieces cool down.

To create a hermetic seal, glass must first be heated to a molten consistency. This occurs at between 1,400 and 1,600 degrees Celsius. Once this happens, the glass can be wetted to the metal. Wetting contacts a liquid with a solid surface through intermolecular interactions. Cohesive and adhesive forces must balance adequately for wetting to succeed.

When the glass-to-metal sealing process is complete, you have a high-quality seal that can handle extreme conditions. Besides mitigating power loss, a good hermetic seal also protects against water and foreign body entry.

Dependability and Durability

Lithium batteries have a wide range of applications. Both durability and reliability are key when it comes to battery end seals. Whether on batteries powering pacemakers, weapons systems or other critical pieces of equipment, Complete Hermetics produces consistently high-quality hermetically sealed components.