In environments where failure is not an option—such as aerospace, medical, and defense systems—hermetic products play a crucial role in protecting sensitive electronics. Among them, hermetic headers stand out for their unmatched ability to shield internal components from moisture, corrosive gases, extreme temperatures, and pressure fluctuations. Trusted across mission-critical applications, these components are the silent protectors of performance and safety.

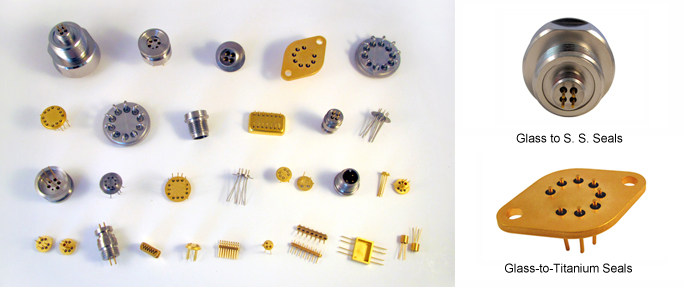

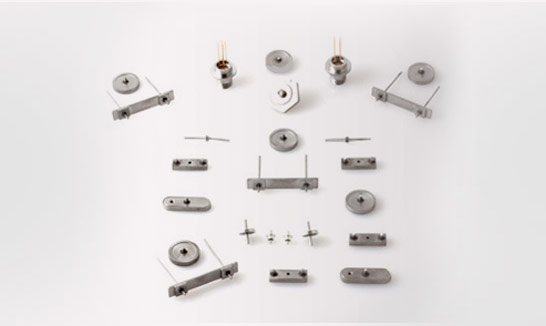

Precision-Engineered Hermetic Headers

At the heart of many electronic assemblies lies the glass to metal seal or ceramic to metal seal, ensuring airtight integrity. These technologies, central to the design of hermetic headers, prevent environmental ingress while supporting high electrical insulation and mechanical strength. From satellite modules to surgical implants, these headers maintain operational stability under the harshest conditions.

Multi Pin Headers: Designed for Demanding Interfaces

Custom hermetic feedthroughs like multi pin headers offer seamless signal transfer between sealed environments. These components are key for data, power, and signal continuity while preserving the integrity of the system. In scenarios where life or mission success depends on reliability, such as avionics or pacemakers, these headers are indispensable.

TO Headers for Optoelectronic Precision

TO headers, or Transistor Outline headers, are optimized for optical and high-frequency applications. Often integrated into TOSA and ROSA assemblies, they enable superior performance in communication systems. Every TO header from Complete Hermetics is carefully tailored to meet your exact specifications—ensuring reliability in both space-limited and heat-sensitive environments.

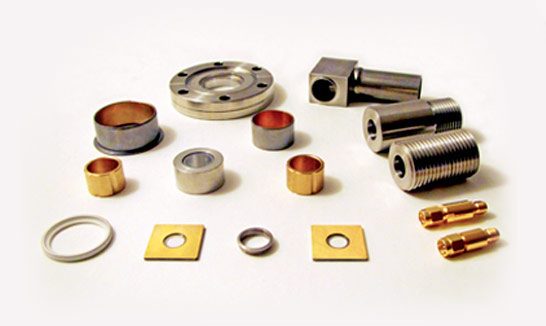

Hermetic Connectors: Dependable Sealing for Complex Systems

Whether used in subsea installations or vacuum chambers, hermetic connectors provide robust sealed interfaces between different electronic units. These connectors, available in standard or custom hermetic feedthroughs, protect against system failure by maintaining perfect seals under dynamic pressure and thermal stress.

Partner with Complete Hermetics for Hermetic Excellence

As a premier hermetic seal manufacturer, Complete Hermetics delivers cutting-edge solutions, including hermetic headers, hermetic connectors, and custom-engineered seals. Our proven expertise in glass to metal seals and ceramic to metal seals ensures that your technology remains protected from the elements. Explore our complete line of hermetic products today and experience the precision and performance only Complete Hermetics can deliver.

Contact Complete Hermetics today to explore our full line of hermetic products.