Hermetic sealed connectors are important in regards to system integrity maintenance. These connectors may be used in aerospace operations or military. They may be used in gas-tight barriers and may have to withstand extreme pressures. It’s important that you can optimize your connectors to match your requirements.

Environmental Factors

To customize hermetics, you must consider harsh or hostile environments. Will your hermetic connectors be exposed to vibration, shock or thermal changes? You have to factor the environment and conditions into the design. You may also need to choose between different plating requirements. You can choose from tin, nickel and both hard and soft golds.

Testing Required

In the planning stages of the design, testing requirements are considered. These aspects are discussed at length and most qualification tests can be performed during assembly. The types of testing that hermetic sealed connectors may have to undergo include:

- Pressure testing

- Leak testing

- Geometrical testing

- Electrical testing

- Insulation resistance

- Voltage

In addition to testing, quality seals are inspected thoroughly.

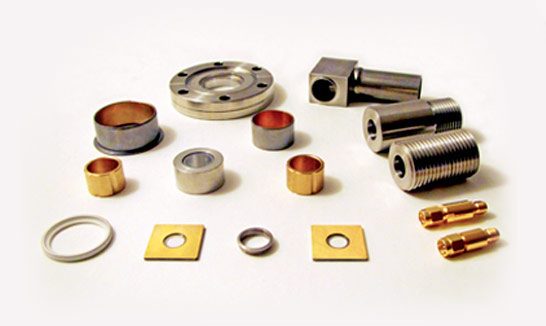

To design hermetic connectors, there are ranges of materials that may be used in the process. From glass to metal seals and advanced sealing techniques, there are options for a variety of connectors. When receiving custom connectors, it is crucial that you address all of your different requirements.