What Are High-Pressure Hermetic Seals?

High-pressure hermetic seals are designed to maintain a completely air-tight and gas-tight barrier in systems exposed to extreme pressure differentials. Hermeticity is defined as the state of being air or gas tight, and in interconnect applications, it refers to sealing technology that prevents gases from passing through pressure boundaries via connectors or feedthroughs. A classic hermetic application is a receptacle feedthrough penetrating a pressurized bulkhead or sealed equipment housing.

Why Pressure Integrity Matters

In high-pressure systems, even microscopic leaks can result in pressure loss, corrosion, electrical failure, or safety risks. Hermetic seals prevent gas migration while preserving electrical insulation and mechanical stability. This makes them essential in environments where reliability and safety are non-negotiable.

Custom Hermetic Sealing Solutions

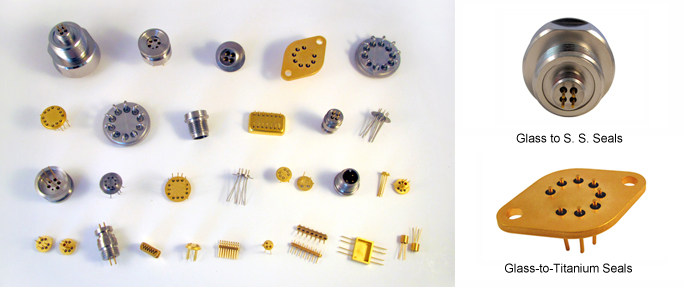

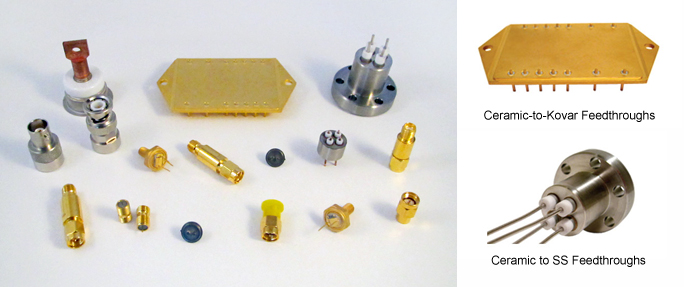

Complete Hermetics specializes in custom hermetic products, including hermetically sealed connectors, hermetic headers, hermetic packages, hermetic seals, and hermetic feedthroughs. Every seal is engineered to meet specific pressure, temperature, and environmental requirements. Advanced modeling and prototyping capabilities allow precise optimization before production.

From Prototypes to Production

Whether customers require small-scale manufacturing for prototypes or mass production for thousands of components, Complete Hermetics supports the full lifecycle. The company works closely with customers to ensure exact specifications are met, regardless of application complexity.

Serving Global Industries

Located in Santa Ana, California, Complete Hermetics serves customers worldwide in aerospace, defense, energy, medical, offshore drilling, and industrial systems. High-pressure hermetic seals are widely used in pressurized vessels, downhole drilling tools, aerospace systems, and military equipment.

Contact Complete Hermetics Today

Complete Hermetics guarantees customer satisfaction through close collaboration, engineering expertise, and rigorous quality standards. Each hermetic seal is designed to perform reliably under extreme pressure and environmental stress.

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com