Why Manufacturer Expertise Matters

Choosing the best hermetic product manufacturer is critical for systems that operate in extreme environments. Hermetic components must meet exacting standards for leak integrity, electrical performance, and mechanical durability. Poor manufacturing quality can result in system failure, safety risks, and costly downtime.

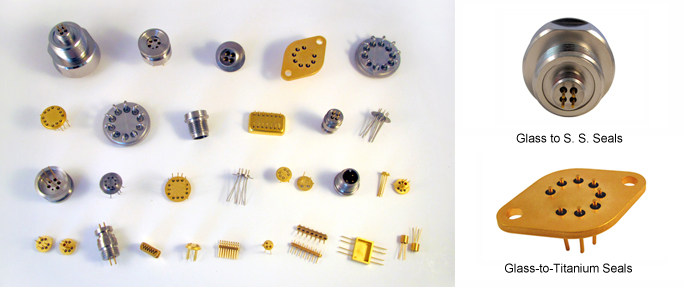

Comprehensive Hermetic Product Portfolio

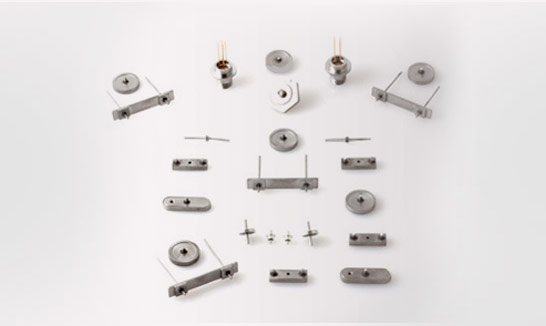

Complete Hermetics designs and manufactures a full range of custom hermetic products, including:

- Hermetic seals

- Hermetic connectors

- Hermetic feedthroughs

- Hermetic headers

- Battery end seals

- Hermetic packages

- High-vacuum viewports

Custom Engineering and Prototyping

Unlike standard suppliers, Complete Hermetics focuses on custom hermetic solutions. The engineering team works closely with customers to develop prototypes, validate designs, and transition seamlessly into production. This collaborative approach minimizes risk and ensures optimal performance.

Advanced Manufacturing Capabilities

From glass-to-metal and ceramic-to-metal sealing to brazing and soldering, Complete Hermetics maintains strict process control and quality standards. The company supports both low-volume specialty projects and large-scale production programs.

Industries Served Worldwide

Hermetic products from Complete Hermetics support aerospace, defense, medical, semiconductor, energy, and industrial markets, where failure is not an option. Customers worldwide rely on the company’s expertise and consistency.

Partner with Complete Hermetics

As a trusted hermetic product manufacturer, Complete Hermetics delivers precision, reliability, and flexibility from design through production. Our engineering team collaborates closely with customers to develop custom sealing solutions that meet demanding electrical, mechanical, and environmental requirements. Using advanced materials, proven glass-to-metal and ceramic-to-metal technologies, and strict quality control, we ensure consistent performance in mission-critical, high-reliability applications across aerospace, medical, energy, and industrial markets.

📞 Phone: 714-265-1238

📧 Email: info@completehermetics.com

🔗 Contact Form

Choose Complete Hermetics for precision sealing solutions built to perform in critical environments.