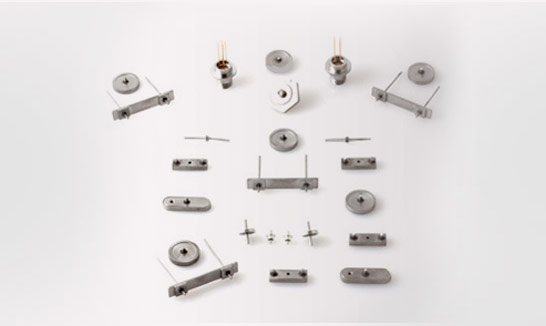

Lithium battery seals employ the incredibly dynamic hermetic seal technology, which effectively makes the objects that are protected by them airtight. These seals can be applied to a large number of materials and are employed in a vast range of industries.

How Are Lithium Battery Seals Designed?

In the lithium battery design, the cells are all individually sealed and cannot leak. This benefits users because there is no restriction orientation of a lithium battery, which means that the battery can be installed upside down or on its side.

Hermetic connectors are a special class of sealed connectors that incorporate glass-to-metal or other highly-engineered sealing technology. Hermetic seal connectors are versatile and dynamic and are employed in a number of diverse applications, including submarines and satellites.

Whether you’re talking about hermetic seals and feedthroughs, battery seals, connectors or any other type of hermetic technology, this type of sealing is designed to ensure an absolute line of demarcation between the object and any other elements.

How Important Are Lithium Battery Seals?

Lithium battery seals prolong the life of your battery. Battery end seals also help to ensure that the battery doesn’t get too hot. The seals also prevent the emission of harmful gas and liquids. Contact Complete Hermetics today to get a quote or if you have any questions about our products and services.