When Ceramic-to-Metal Seals Are Required

Ceramic-to-metal seals are selected when operating conditions exceed the temperature, voltage, or durability limits of glass-to-metal sealing technologies. These seals are engineered for extreme environments where high electrical isolation, thermal stability, and long-term reliability are essential. Applications involving high voltage, high temperature, vacuum, or radiation exposure often require ceramic sealing solutions to ensure performance and safety.

Advanced Ceramic Sealing Technology

Ceramic-to-metal seals are typically manufactured using high-purity alumina ceramics combined with metallization and brazing processes. The ceramic provides exceptional dielectric strength and thermal resistance, while the metal components ensure mechanical integrity and compatibility with system housings. This combination allows ceramic seals to maintain hermeticity under severe thermal cycling and electrical stress.

Mechanical and Electrical Performance

Unlike glass, ceramic materials maintain dimensional stability at very high temperatures and exhibit minimal deformation under load. This makes ceramic-to-metal seals ideal for applications where electrical insulation must remain stable over extended operating periods. Their resistance to arcing and electrical breakdown further enhances safety in high-voltage systems.

Extreme Conditions and Long-Term Stability

Ceramic-to-metal seals also perform exceptionally well in vacuum and radiation-sensitive environments due to their low outgassing and material purity. While these seals are more complex and time-intensive to manufacture than glass seals, their durability and performance justify their use in mission-critical systems where failure is unacceptable.

High-Performance Applications

Common applications include aerospace propulsion systems, medical imaging probes, vacuum chambers, semiconductor processing equipment, high-temperature sensors, and defense electronics. These environments demand sealing solutions that can withstand prolonged exposure to heat, pressure, and electrical stress without degradation.

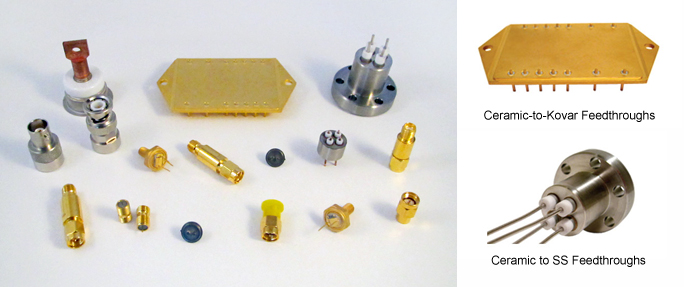

Contact Complete Hermetics

Complete Hermetics designs and manufactures custom ceramic-to-metal seals and feedthroughs, along with glass-to-metal seals, hermetic connectors, hermetic headers, and hermetically sealed packages for extreme environments. The company also supports specialized requirements with custom hermetic feedthroughs, power packages, and custom hermetic solutions tailored to demanding applications. By combining advanced materials with precision engineering, Complete Hermetics delivers sealing technologies customers can rely on.

- Website: www.completehermetics.com

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com