Why Hermetic Seals Are Essential

Medical hermetic seals play a critical role in ensuring the safety, reliability, and biocompatibility of implantable and diagnostic electronics. When devices operate inside the human body or are exposed to sterilization processes, they must withstand moisture, bodily fluids, chemical exposure, and extreme thermal variations. Even the smallest leak can cause internal corrosion, signal failure, or biological contamination. As modern medical devices become smaller yet more capable, the demand for advanced hermetic sealing technologies grows significantly.

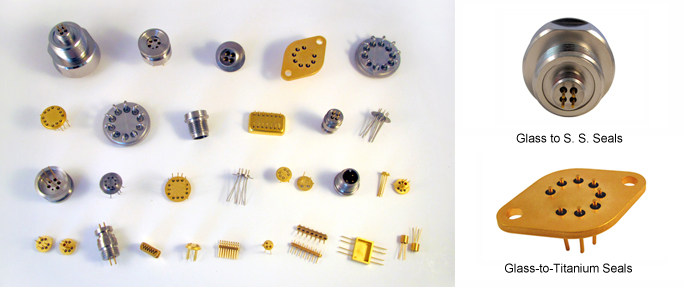

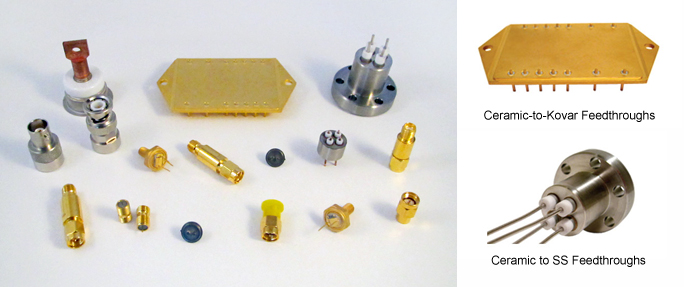

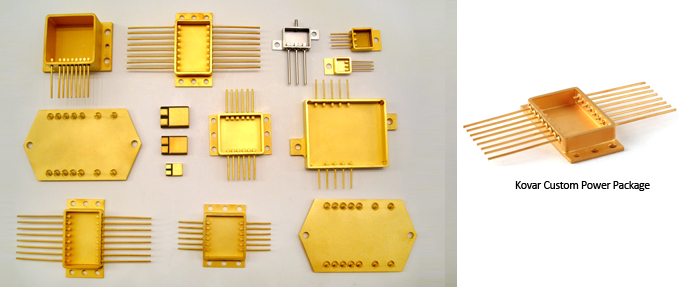

Glass-to-Metal & Ceramic-to-Metal Sealing Technologies

Complete Hermetics designs medical-grade seals using glass-to-metal (GTM) and ceramic-to-metal (CTM) sealing methods. Glass seals provide cost-effective, high-strength bonding between metal housings and conductive pins, while ceramic seals are ideal for high-voltage or long-term implants due to their exceptional dielectric strength. Using materials such as titanium, stainless steel, and high-purity alumina ceramics, these seals are engineered to perform reliably in demanding biological environments.

Regulatory-Ready Testing & Biological Safety

Medical hermetic seals must meet FDA, ISO 14708, IEC 60601, and biocompatibility standards. Complete Hermetics performs rigorous testing—including helium leak detection, sterilization simulation, thermal shock, electrical insulation analysis, and X-ray inspection—to ensure every seal meets life-critical reliability requirements. Traceability, cleanliness, and manufacturing consistency are maintained at every step.

Applications in Modern Healthcare

Medical hermetic seals enable secure operation in:

- Pacemakers & implantable cardioverter defibrillators (ICDs)

- Neurostimulation & pain-management implants

- Implantable batteries & power modules

- Surgical navigation tools

- Diagnostic imaging equipment

- Long-term biosensor implants

Contact Complete Hermetics

For precision-engineered medical hermetic seals that support life-critical technology, trust the expertise of Complete Hermetics.

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com