The terms Vacuum Feedthrough, Electric Feedthrough, Glass Feedthrough or Glass-to-Metal Feedthrough, Ceramic Feedthrough or Ceramic-to-Metal Feedthrough are often used interchangeably in vacuum and hermetic sealing industries. However, all serve a common purpose: enabling secure and reliable passage of electrical current or signals in systems requiring airtight protection.

What is a Hermetic Feedthrough?

The primary function of a hermetic feedthrough is to carry electrical current to and from a hermetic or vacuum system while maintaining the airtight integrity of the system. Hermeticity refers to the condition of being completely airtight, ensuring that gases cannot pass through the system. This technology is critical in applications where maintaining a controlled environment is paramount.

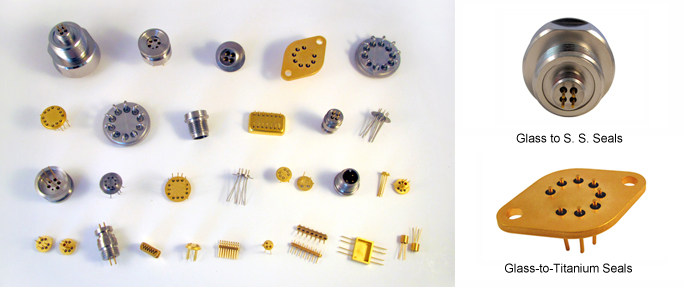

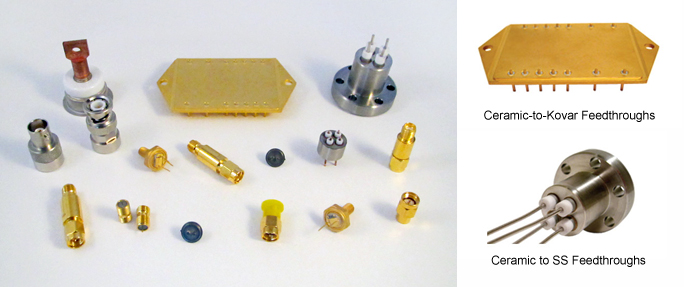

Custom Hermetic Feedthroughs for Precision Applications

Complete Hermetics specializes in the design and manufacture of custom hermetic feedthroughs tailored to meet the unique needs of various industries. From glass-to-metal feedthroughs to ceramic-to-metal feedthroughs, our products are engineered for precision and reliability. We also offer laser-welded and solder-in installation options for enhanced durability.

Our feedthroughs find applications in:

- Submersible Pumps

- Downhole Instrumentation

- Exploratory and Implant Medical Devices

- Cryogenic Medical Probes

Multi-Pin Hermetic Feedthroughs and Electrical Bulkhead Solutions

For systems requiring multiple electrical connections, our multi-pin hermetic feedthroughs and electrical bulkhead hermetic feedthroughs provide a reliable solution. These feedthroughs are designed to withstand high pressures and extreme environments, ensuring uninterrupted performance in applications like downhole drilling and surgical equipment.

Durability and High Performance

Complete Hermetics manufactures products capable of performing in the most challenging conditions. Whether in deep-sea submersible pumps or cryogenic medical probes, our custom hermetic connectors and hermetic packages ensure reliable operation and long-term durability.

Choose Complete Hermetics for Your Hermetic Seal Needs

Complete Hermetics is your trusted partner for high-quality, reliable solutions. With a focus on innovation and precision, we deliver products that exceed industry standards. Contact us today to learn how our hermetic feedthroughs, hermetic seals, and related technologies can meet your specific needs. Let us assist you in achieving airtight performance for your systems.

Visit Complete Hermetics now to explore our advanced solutions and request a quote!