As you may know, hermetic feedthroughs allow energy or substances to migrate from outside a hermetically-sealed area to the inside. Maintaining hermetic seals is important with a feedthrough, but providing electrical isolation is also key. Strict performance standards call for no leakage while ensuring that a powerful vacuum remains.

Constructing Hermetic Feedthroughs

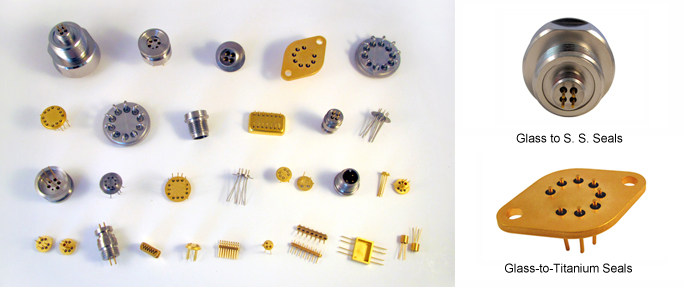

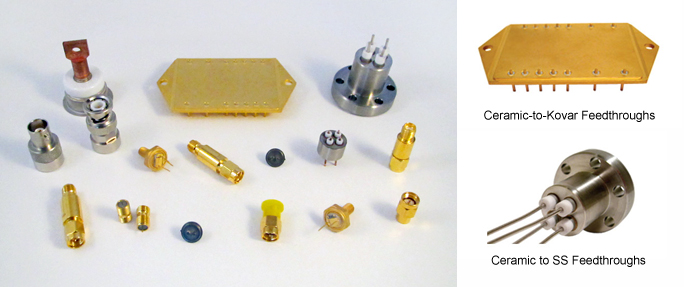

A hermetic feedthrough is created using similar techniques to creating hermetic seals. Its glass-to-metal construction incorporates molten glass that can be bonded tightly to metal. To achieve this feat, the glass must be heated to between 1,400 and 1,600 degrees Celsius. Some feedthroughs incorporate ceramic-to-metal or electrical sealing. Hermetic feedthroughs can fall into one of three unique categories:

- Low-voltage

- Water-cooled/RF

- High-voltage

Critical Performance Standards

A high-quality feedthrough can resist extreme temperature shifts, changes in pressure and huge swings in humidity levels. When plated, feedthroughs can also resist corrosion and handle wire bonding or soldering. Depending on product specifications, a feedthrough may need to tolerate even more extremes without so much as a tiny amount of leakages. For feedthroughs used in medical equipment, such super-strict production standards are necessary.

Complete Hermetics develops and manufactures hermetic seals and feedthroughs that deliver the dependability and durability needed in your applications. Besides our standard feedthroughs, we can also design custom versions that meet your needs. Call us at (714) 265-1238 or fill in the contact form for your needs of hermetic seals and feedthroughs now.