Purpose of Battery End Seals

Battery end seals are critical hermetic components that protect internal battery elements from moisture, gas leakage, and contamination while allowing safe electrical connectivity. In lithium battery seals, maintaining hermetic integrity is essential to prevent performance degradation and safety hazards.

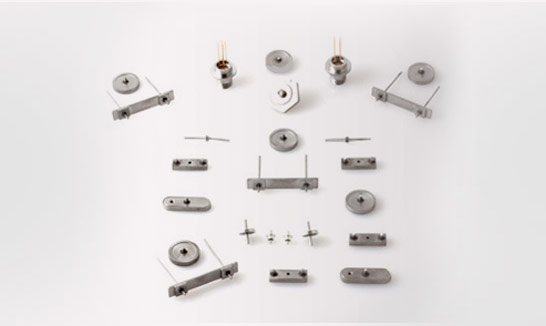

Glass-to-Metal Sealing for Batteries

Complete Hermetics utilizes advanced glass-to-metal sealing technologies proven to be highly reliable for battery end seals and capacitor lids. The molten glass bonds to metal housings and terminals, creating a robust hermetic and electrically insulating seal ideal for high-energy applications.

Performance in Harsh Conditions

Battery end seals are engineered to withstand extreme temperatures from –40°C to over +150°C, electro-chemical corrosion, humidity exposure, pressure variation, and high electrical currents. This durability ensures stable battery operation across long service lifetimes and demanding environments.

Testing and Quality Assurance

To ensure safety and performance, Complete Hermetics conducts 100% leak testing using helium mass spectrometry. The minimum leak rate is ≤ 1 × 10⁻⁸ cc He/sec. Additional testing such as high electrical isolation resistance and breakdown voltage testing can be performed as required.

Materials and Customization

Battery end seals are available in a wide range of materials:

- Body materials: Stainless steel, mild steel, titanium, aluminum

- Pin materials: Alloy 52, molybdenum, stainless steel, titanium

- Glass materials: Corning 9010, 9013, TA23, Cabal 12, or custom glass formulations

Applications Across Industries

Battery end seals are used in medical equipment, communication systems, weapon systems, sensors, monitoring devices, and automotive electronics, where safety and reliability are critical.

Contact Complete Hermetics for Hermetic Solutions

Complete Hermetics specializes in battery end seals designed for maximum performance, safety, and durability. The company also manufactures advanced battery feedthroughs, glass-to-metal lids, and other reliable hermetic components engineered to endure the most demanding conditions. Leveraging precision manufacturing and proven sealing technologies, every product delivers dependable, long-term reliability.

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com