Purpose of Battery End Seals

Battery end seals are critical hermetic components designed to protect internal battery elements from moisture, gas leakage, corrosion, and environmental exposure while allowing safe electrical connectivity. In high-energy battery systems—especially lithium battery seals—even minor leakage can result in performance degradation, safety hazards, or premature failure. Hermetic battery end seals ensure long-term containment and electrical stability in demanding operating environments.

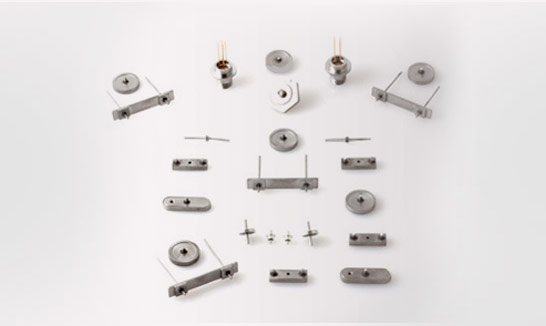

Glass-to-Metal Sealing Technology for Batteries

Complete Hermetics utilizes advanced custom glass-to-metal sealing technologies that have proven highly reliable for battery end seal manufacturing. In this process, glass is heated to a controlled molten state and bonded to metallic housings and terminals, forming a robust, airtight, and electrically insulating seal. This technology is especially well suited for lithium battery end covers and capacitor lids, where consistent hermeticity and electrical isolation are mandatory.

Performance in Harsh Environments

Battery end seals manufactured by Complete Hermetics are engineered to withstand extreme environmental conditions, including wide temperature ranges from –40°C to over +150°C, electro-chemical corrosion, humidity exposure, pressure variation, and high electrical currents. These characteristics make them suitable for both portable and stationary energy systems operating in unpredictable or harsh conditions. The glass-to-metal interface provides excellent resistance to thermal cycling and long-term chemical exposure, ensuring stable performance throughout the battery’s lifecycle.

Testing, Inspection, and Reliability Assurance

To guarantee performance and safety, Complete Hermetics conducts 100% leak testing on battery end seals using helium mass spectrometry. The minimum guaranteed leak rate is ≤ 1 × 10⁻⁸ cc He/sec, ensuring exceptional hermetic integrity. When required, additional testing such as high electrical isolation resistance and dielectric breakdown voltage testing can be performed to meet customer or regulatory requirements. This rigorous inspection process supports use in mission-critical applications.

Material Specifications and Customization

Battery end seals are available in a wide range of material combinations to match application-specific requirements.

Body materials include stainless steel, mild steel, titanium, and aluminum, offering strength, corrosion resistance, and weight optimization.

Pin materials include Alloy 52, molybdenum, stainless steel, and titanium, selected for electrical performance and thermal compatibility.

Glass materials include Corning 9010, Corning 9013, TA23, Cabal 12, and custom glass formulations upon request.

Applications Across Industries

Hermetic battery end feedthrough seals are widely used in medical and healthcare equipment, communication systems, weapon systems, sensor and monitoring devices, automotive electronics, and energy storage systems where safety and reliability are paramount.

Contact Complete Hermetics Today for Your Reliable Hermetic Products

Complete Hermetics is a custom manufacturer of battery end seals, lithium battery glass-to-metal sealed lids, capacitor end seals, and other precision hermetic components engineered for extreme environments. In addition to battery sealing solutions, the company also offers custom ceramic-to-metal seals and feedthroughs, along with glass-to-metal seals, hermetic connectors, hermetic headers, and hermetically sealed packages for aerospace, defense, medical, energy, and industrial applications. From prototype development through full-scale production, Complete Hermetics delivers reliable hermetic technologies backed by rigorous testing and deep engineering expertise.

- Website: www.completehermetics.com

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com