Hermetic seals and feedthroughs are essential in industries that require airtight, corrosion-resistant, and high-temperature-capable components. From aerospace to medical devices, these components protect critical systems from environmental damage. Below are 15 top FAQs with concise answers to help you understand these vital technologies.

1. What is a hermetic seal?

A hermetic seal is an airtight and moisture-proof seal that prevents gas or fluid leakage between joined components.

2. What is a hermetic feedthrough?

A hermetic feedthrough allows electrical signals or power to pass through a sealed barrier without compromising the seal’s integrity.

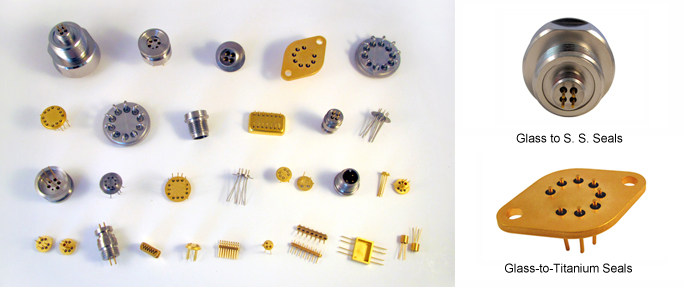

3. What are glass-to-metal seals?

These glass-to-metal seals fuse molten glass with metal under controlled thermal expansion to create a strong, durable, and airtight bond.

4. What’s the difference between matched and compression seals?

Matched seals use materials with similar thermal expansion rates; compression seals use mismatched rates for higher strength and pressure resistance.

5. What applications use hermetic feedthroughs?

They are used in aerospace, military, medical implants, vacuum systems, and oil & gas instrumentation.

6. What materials are used in glass-to-metal seals?

Common materials include Kovar, stainless steel, Inconel, and alkali barium glass.

7. What’s the leak rate standard?

Complete Hermetics’ products meet or exceed 1×10⁻⁹ atm cc/sec He for superior hermeticity.

8. Are custom designs available?

Yes. Complete Hermetics offers fully customized solutions tailored to specific dimensions, materials, and electrical specs.

9. What are ceramic-to-metal seals used for?

For high-voltage, high-temperature, and corrosive environments that glass cannot withstand.

10. How do ceramic-doped glass seals differ?

They offer high thermal resistance (up to 600°C) at a lower cost than traditional ceramic-to-metal seals.

11. What plating options are available?

Platings include gold, silver, electroless nickel, and tin for corrosion resistance and solderability.

12. Can hermetic seals be used in medical devices?

Absolutely. Titanium terminals and headers are ideal for batteries, sensors, and diagnostic tools.

13. What electrical specs can be expected?

Typical insulation resistance exceeds 1 GΩ @ 100 VDC; dielectric strength depends on glass type.

14. What shapes and sizes are available?

Circular, rectangular, micro-D and custom headers are available across a wide range of standard and custom sizes.

15. Can feedthroughs handle high pressure?

Yes. Compression seals can withstand pressures up to 14,000 PSI, depending on design.

Why Choose Complete Hermetics?

Complete Hermetics is a leading custom manufacturer of glass-to-metal, ceramic-to-metal, and hermetic feedthroughs and seals. Our expert team designs hermetic connectors, headers, packages, and vacuum viewports to fit your exact requirements. Whether you’re in aerospace, defense, medical, or industrial sectors, we deliver high-performance, leak-proof solutions with precision and reliability.

📞 Phone: 714-265-1238

📧 Email: info@completehermetics.com

🔗 Contact Form: Complete Hermetics Contact

Contact Complete Hermetics today – your partner in precision sealing solutions.