What Is a Vacuum Feedthrough?

Vacuum feedthroughs allow electrical current or signals to pass into or out of hermetic or vacuum systems while maintaining airtight integrity. The terms vacuum feedthrough, electric feedthrough, glass feedthrough, and ceramic feedthrough are often used interchangeably, but all serve the same fundamental purpose: preserving hermeticity across pressure boundaries.

Importance of Hermeticity in Electrical Systems

In electrical and vacuum systems, hermeticity prevents gas leakage that can disrupt pressure stability or damage sensitive electronics. Feedthroughs must maintain electrical insulation and mechanical strength under thermal cycling, vibration, and pressure variation.

Glass-to-Metal and Ceramic-to-Metal Options

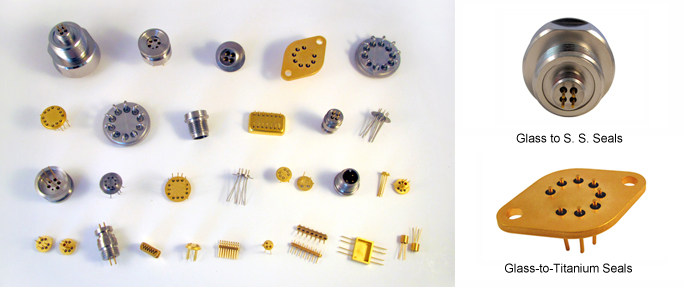

Complete Hermetics manufactures both glass-to-metal feedthroughs and custom ceramic-to-metal feedthroughs. Glass-to-metal feedthroughs are cost-effective and reliable for moderate temperatures and pressures, while ceramic-to-metal feedthroughs support higher voltages, higher temperatures, and harsher environments.

Custom Feedthrough Configurations

Vacuum electrical feedthroughs can be customized with multi-pin layouts, bulkhead mounting, and laser-welded or solder-in contacts to meet specific electrical and mechanical requirements. Custom configurations allow engineers to optimize space, reduce leak paths, and improve system integration.

Applications in Critical Industries

Vacuum electrical feedthroughs are essential in aerospace, medical technology, semiconductor manufacturing, energy systems, and scientific research, where reliable electrical penetration of sealed environments is required.

Contact Complete Hermetics Today for Your Hermetic Capabilities

Complete Hermetics designs and manufactures vacuum feedthroughs, glass-to-metal feedthroughs, ceramic-to-metal feedthroughs, hermetic connectors, and hermetic headers for extreme environments. In addition, the company provides battery end seals, TO headers, power packages and custom hermetic solutions to support complex systems. From engineering support to production, Complete Hermetics delivers dependable hermetic feedthrough technology worldwide.

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com