How Glass-to-Metal Seals Work

Glass-to-metal seals are created by heating glass to a molten state and bonding it directly to metal under carefully controlled conditions. As the materials cool, the glass forms a strong, hermetic bond with the metal, creating an airtight and electrically insulating seal. This process allows electrical conductors to pass through metal housings without permitting moisture, gas, or contaminants to enter the sealed environment. Because of their proven reliability, glass-to-metal seals remain one of the most widely used hermetic sealing technologies across multiple industries.

Performance Advantages of Glass Sealing

One of the key advantages of glass-to-metal seals is their ability to maintain hermetic integrity under pressure changes, humidity exposure, and moderate temperature extremes. Glass provides excellent dielectric strength, corrosion resistance, and chemical stability, making it suitable for long-term use in harsh environments. Compared to epoxy or mechanical sealing methods, glass-to-metal seals offer significantly longer service life and more predictable performance over time.

Material Compatibility and Stability

Successful glass-to-metal sealing depends on matching the coefficient of thermal expansion (CTE) between the glass and metal components. Materials such as Kovar, Alloy 52, stainless steel, and copper-based alloys are commonly used to achieve this balance. When properly engineered, these seals tolerate thermal cycling and mechanical shock without cracking or leakage, making them suitable for both static and dynamic applications.

Manufacturing Precision and Repeatability

Glass-to-metal sealing requires precise control over glass composition, firing temperature, and cooling rates. This level of control ensures consistent quality and repeatability across production runs. As a result, glass-to-metal seals are ideal for both prototype development and high-volume manufacturing, allowing manufacturers to scale production without sacrificing reliability.

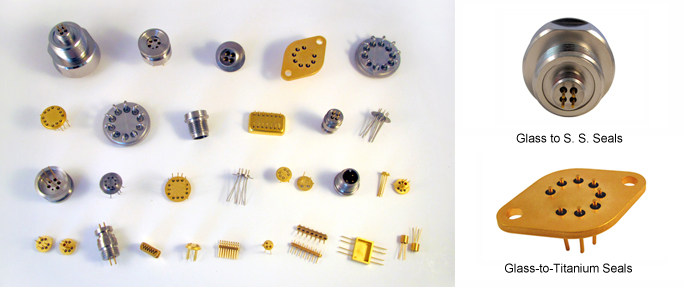

Common Applications

Glass-to-metal seals are widely used in glass-to-metal sealed lids, battery end seals, capacitor end seals, sensors, medical implants, and industrial electronics. They are also commonly found in automotive systems, pressure sensors, and energy storage devices where cost-effective hermetic performance is required.

Contact Complete Hermetics

Complete Hermetics is a custom manufacturer of hermetic sealing solutions, specializing in glass-to-metal seals, ceramic-to-metal seals, hermetic connectors, hermetic feedthroughs, hermetic headers, TO headers, vacuum feedthroughs, and battery end seals. The company designs and produces hermetically sealed components and custom hermetic assemblies for aerospace, defense, medical, energy, and telecom applications, delivering reliable performance in extreme environments from prototype development through full-scale production, backed by deep engineering expertise.

- Website: www.completehermetics.com

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com