Why Vacuum Feedthroughs Are Critical

Vacuum feedthroughs are specialized hermetic components that allow electrical power or signals to pass through vacuum or pressure barriers without leakage. Even microscopic leaks can compromise vacuum integrity, contaminate sensitive processes, or disrupt system performance. As a result, vacuum feedthroughs are essential in applications requiring precise environmental control.

High-Vacuum and Bulkhead Designs

Hermetic bulkhead feedthroughs provide multiple electrical pathways through a single flange-mounted interface. This design reduces the number of enclosure penetrations, improving system reliability and simplifying installation. Bulkhead feedthroughs are commonly used in high-vacuum chambers, pressure vessels, and sealed instrumentation housings.

Material Compatibility and Precision Engineering

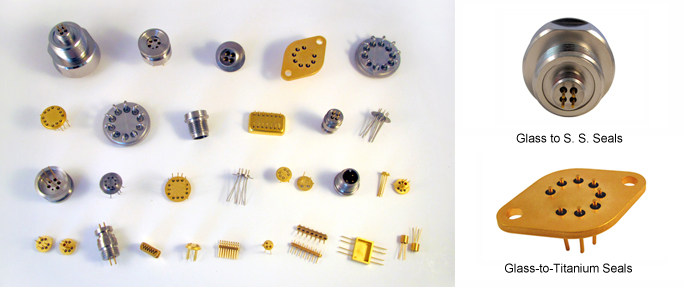

Vacuum feedthroughs are manufactured using materials such as stainless steel, Kovar, titanium, and high-purity ceramics to ensure compatibility with vacuum environments. These materials exhibit low outgassing, excellent thermal stability, and corrosion resistance. Precision manufacturing and sealing techniques are required to meet stringent leak-rate specifications, often verified through helium leak testing.

Performance in Sensitive Systems

In vacuum systems, performance margins are extremely narrow. Feedthroughs must maintain electrical insulation, mechanical stability, and hermetic integrity under thermal cycling, vibration, and pressure differentials. Poorly designed feedthroughs can lead to system downtime, safety risks, or costly repairs.

Critical Applications

Vacuum feedthroughs are widely used in semiconductor fabrication equipment, aerospace simulation chambers, research laboratories, medical imaging systems, and high-energy physics instrumentation.

Contact Complete Hermetics Today for Your Hermetic Solutions

Complete Hermetics designs and manufactures custom vacuum feedthroughs and hermetic bulkhead feedthroughs, including multi-pin configurations, glass-to-metal and ceramic-to-metal seals, and vacuum-rated assemblies. The company also supplies hermetic connectors, headers, hermetic packages, and battery end seals to support fully integrated systems. With rigorous testing and precision engineering, Complete Hermetics delivers vacuum solutions customers can depend on.

- Contact Form: https://www.completehermetics.com/contact-us/

- Website: www.completehermetics.com

- Phone: 714-265-1238

- Email: info@completehermetics.com