When it comes to reliable hermetic products, precision engineering and proven expertise are non-negotiable. As a top hermetic manufacturer, Complete Hermetics leads the industry with custom solutions for highly demanding environments. Specializing in glass-to-metal and ceramic-to-metal seals, the company develops advanced components tailored for aerospace, defense, medical devices, semiconductors, and energy systems.

Engineered for Performance in Extreme Environments

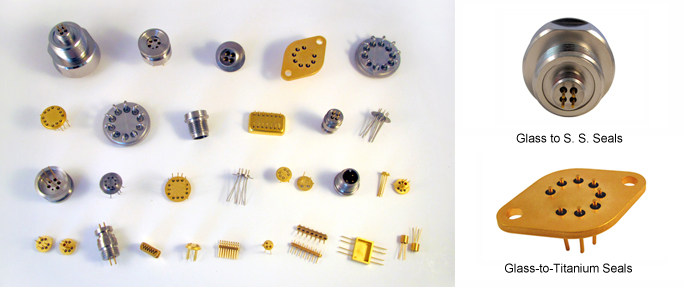

Whether you’re operating in vacuum, high-pressure, or high-temperature environments, Complete Hermetics offers components that ensure absolute sealing integrity. Their portfolio includes hermetic connectors, hermetic feedthroughs, and hermetic headers—all designed with precision to maintain signal integrity and eliminate the risk of leakage or contamination. These hermetic solutions are ideal for applications where failure is not an option.

Innovation in Hermetic Packaging and Integration

From hermetic packages to custom battery end seals and vacuum viewports, Complete Hermetics delivers advanced materials integration and performance. Their in-house expertise in brazing and soldering allows for tailored assemblies that meet rigorous industry and military specifications. Every component is engineered to maintain mechanical and electrical performance in the most demanding operating conditions.

Reach out to Complete Hermetics today to learn how our advanced solutions can improve the reliability and efficiency of your applications. We also offer expert customization in hermetic connectors, vacuum viewports, and hermetic headers designed to meet your precise requirements.