Understanding Electrical Feedthroughs

Electrical feedthroughs are essential for transmitting power and signals through sealed or vacuum-tight walls while preventing any breach of hermeticity. They are widely used in scientific, aerospace, and industrial applications where reliable current flow must be maintained under vacuum, high voltage, or extreme temperature.

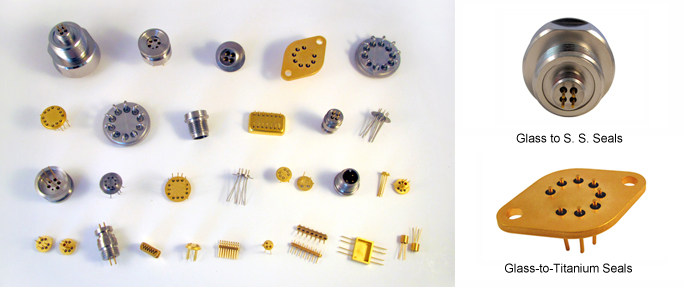

Design and Sealing Technology

Complete Hermetics uses advanced glass-to-metal and ceramic-to-metal bonding to produce leak-free, corrosion-resistant electrical feedthroughs. Each unit isolates conductors from metal housings, ensuring low resistance and high dielectric strength. The company’s process guarantees zero gas permeability and stability under mechanical stress.

Precision Engineering and Testing

Each feedthrough is designed with performance in mind. Options include single-pin and multi-pin configurations. All assemblies undergo vacuum testing, high-voltage dielectric checks, and pressure cycling to confirm absolute reliability before shipment.

Materials and Configurations

Complete Hermetics offers feedthroughs built from stainless steel, Inconel, or Kovar housings with ceramic insulators. Optional surface finishes—gold, nickel, or tin plating—enhance conductivity and solderability. These materials resist corrosion, heat, and wear, ensuring a long operational lifespan even in demanding conditions.

Industrial and Research Applications

- Aerospace propulsion and flight-control systems

- Semiconductor and vacuum-furnace environments

- Particle accelerators and nuclear facilities

- Medical imaging and diagnostic equipment

Contact Complete Hermetics

For dependable electrical feedthroughs that deliver precision, safety, and lasting performance, trust Complete Hermetics—your expert in high-integrity hermetic sealing.

Contact Info:

Contact Form: https://www.completehermetics.com/contact-us/ | Phone: 714-265-1238 | Email: info@completehermetics.com