You might not think that there are many components that can be found in X-ray machines, transformers and furnaces. But electrical feedthroughs are commonly used in a wide variety of technologies to help make sure that electricity doesn’t escape and cause malfunctions. It is important to know what these feedthroughs are used for and to appreciate this important piece of technology that keeps so many different technologies running.

The Importance of Vacuums

Creating a vacuum guarantees that the electricity being transported from one part of a machine to another does not get out. Vacuum feedthroughs effectively make sure that the electricity is distributed safely.

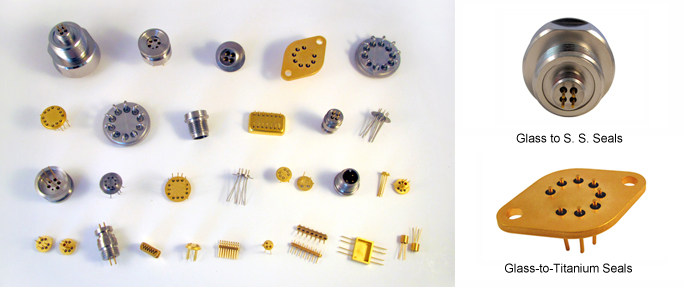

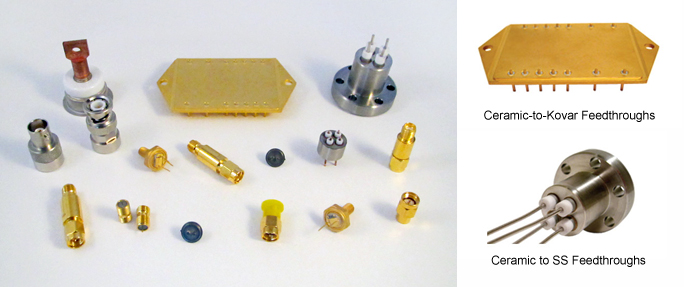

Using Seals

The key to creating a vacuum is the type of seal that is used. Hermetic feedthroughs use glass-to-metal seals and ceramic seals to create this vacuum. When building a new seal, it is extremely important that the materials used are able to withstand intensive use and not break down over time.

This is why many seals are made with glass and ceramics; these materials are designed to withstand extreme temperatures, as well as other wear and tear. Many of these seals are used in technology like furnaces that operate at extreme temperatures. Making sure the seals do not break down easily will make sure the machine runs smoothly.