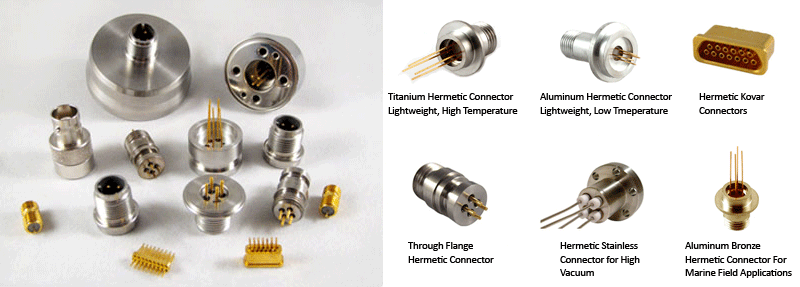

Extremely harsh environments call for extra protection to ensure the integrity of a system. Hermetically sealed connectors provide such protection by keeping all air, moisture and contaminants out. If you’re looking for the right connectors for your application, consider these tips to begin your search.

-

Select the Shell

There are two major types of connector shell shapes: circular and rectangular. Sizes typically range from 0.25 inches to 3.0 inches in diameter. Connectors can be made from a variety of materials such as:

- 300 Series Stainless Steel

- Cold Rolled Steels

- Kovar

- Inconel

- Titanium

- Aluminum

Kovar is a nickel- and cobalt-based alloy that contains iron, and Inconel is a nickel-based alloy that contains iron and chromium. Titanium and aluminum hermetically sealed connectors are lightweight but still provide the same quality of seal as heavier materials.

-

Select the Pins

To select the correct pin configuration, determine how many pins you need and how they need to be oriented. Pin end shapes usually include rounded, eyelet and hook types and range from 4 AWG to 16 AWG in size. Typical pin materials are:

- Kovar and Copper Cored Kovar

- Alloy 52

- Inconel

- Molybdenum

- Stainless Steel

Alloy 52 is composed of nickel and iron and works well for sealing glass to metal, while molybdenum is known for reducing wear and friction.

-

Select the Finish

The finish is important because it protects hermetically sealed connectors from the environment. Standard finishes include:

- Bright Tin Plating

- Electroless/Electrolytic Nickel Plating

- Copper Plating

- Gold Plating

- Silver Plating

Though the finish primarily protects the connector against corrosion, it is also a considered design element that makes your system look sharp. For instance, bright tin plating creates a shiny exterior, while gold plating can make the connectors stand out.

Ask the Pros

If you’re having trouble deciding which hermetically sealed connectors are right for your application, call your dealer for help. The experts can help you select the right size, shape and finish to ensure the integrity of your system.