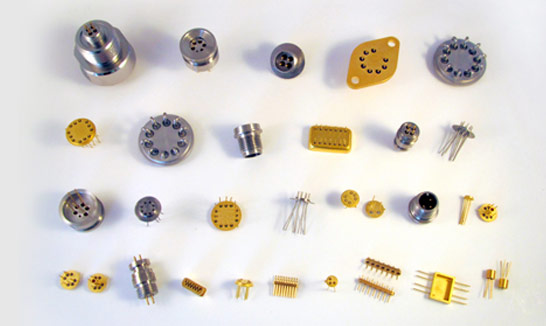

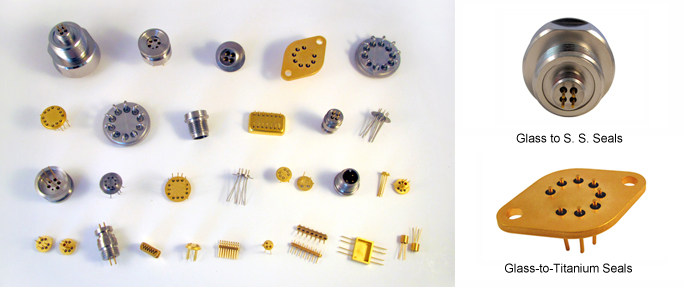

Feedthroughs are an indispensable part of most commercial electrical applications and their accuracy is critical to its success. When working in aerospace, defense and other arenas where extreme conditions are the norm and high reliability is vital, feedthrough performance is even more vital. These are cases where glass to metal hermetic feedthroughs make the most sense. Here are a few other applications where glass-to-metal sealed feedthroughs are the ideal choice.

Medical Applications

Perhaps no environment could be tougher than the human body. When a device must be implanted, a glass-to-metal hermetic feedthrough is the best choice. This type of airtight feedthrough prevents diffusion of gasses and keeps electrical components from corroding when doing so could spell life or death.

Automotive Applications

If a sensor has ever triggered your vehicle’s check engine light, you know how important it is that they work properly. Glass-to-metal feedthroughs are ideal to ensure sensors measuring everything from flow to pressure can function properly.

Industrial Applications

Glass-to-metal seal feedthroughs are commonly used in critical industrial applications, blocking the effects of high temperature and damaging chemicals. In this case, hermetic feedthroughs can also prevent electronic failure caused by humidity or pressure.

Hermetic feedthroughs have countless applications in defense, medical, aerospace, and other fields. Glass-to-metal manufacturing creates the most reliable performance.