Protecting Systems Beneath the Surface

Offshore drilling hermetic solutions are essential for equipment exposed to saltwater, pressure fluctuations, and vibration. Subsea control modules, instrumentation, and power systems all rely on hermetic sealing to maintain performance and safety in one of Earth’s harshest environments.

Why Hermeticity Matters Offshore

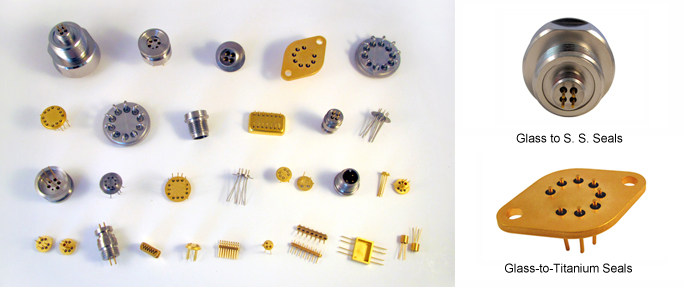

At extreme ocean depths, water intrusion and corrosion can destroy unsealed electronics. Complete Hermetics designs glass-to-metal and ceramic-to-metal seals that prevent leaks even under thousands of PSI. Their seals resist electrochemical corrosion and ensure stable operation in deep-sea and high-salinity conditions.

Applications in Marine and Energy Industries

These hermetic components are used in offshore oil rigs, ROV sensors, subsea pumps, and oceanographic equipment. Their pressure-tested enclosures safeguard data acquisition and control systems used in deep-water exploration.

Engineering for Durability

Complete Hermetics utilizes titanium, Inconel, and stainless steel materials, chosen for their resistance to saltwater oxidation and mechanical fatigue. Each assembly undergoes hydrostatic and helium leak testing to confirm absolute reliability before deployment.

Custom Solutions for Every Project

Whether for shallow-water exploration or ultra-deep drilling, Complete Hermetics works directly with clients to create custom hermetic components optimized for subsea connectors, sensors, and power transmission.

Contact Complete Hermetics

Depend on Complete Hermetics for durable, corrosion-resistant offshore drilling hermetic solutions that protect your systems under the most demanding marine conditions.

Contact Info:

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com