Hermetic feedthroughs in defense applications play a crucial role in ensuring secure, reliable electrical connections across pressurized or vacuum-sealed barriers. These precision-engineered components maintain airtight integrity while transmitting electrical signals or power, making them indispensable for high-performance environments like defense electronics, aerospace, naval systems, and other mission-critical applications. By preventing moisture, gases, and contaminants from breaching the sealed enclosure, hermetic seals preserve the integrity and longevity of sensitive electronics.

Custom Hermetic Feedthroughs Built for the Defense Industry

From radar systems and drones to underwater surveillance equipment, today’s military technologies demand highly robust, custom hermetic feedthroughs that perform under extreme conditions. Complete Hermetics specializes in designing tailored solutions—including multi-pin hermetic feedthroughs and electrical bulkhead hermetic feedthroughs—to fit specific environmental and performance needs.

Whether it’s enduring high pressures in submersible defense systems or maintaining electrical continuity in aircraft sensor arrays, our hermetic solutions are engineered to withstand temperature extremes, vibration, and corrosion. Laser-welded assemblies and vacuum-grade sealing ensure absolute reliability and zero leakage in any scenario.

Advanced Materials: Glass-to-Metal and Ceramic-to-Metal Seals

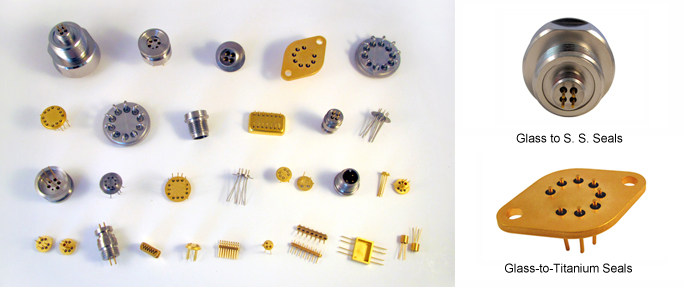

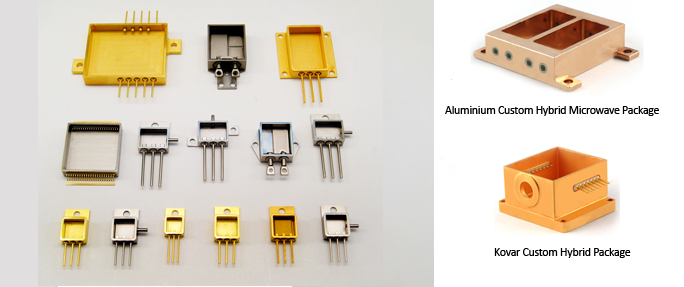

The right choice of materials is essential for optimal performance. At Complete Hermetics, we offer both glass-to-metal and ceramic-to-metal feedthroughs. Glass provides excellent hermeticity and thermal compatibility, while ceramic excels in high-voltage and high-frequency applications. Our engineers work closely with clients to choose the best configuration for durability, dielectric strength, and mechanical stability.

Complete Hermetics: Innovating Hermetic Technology

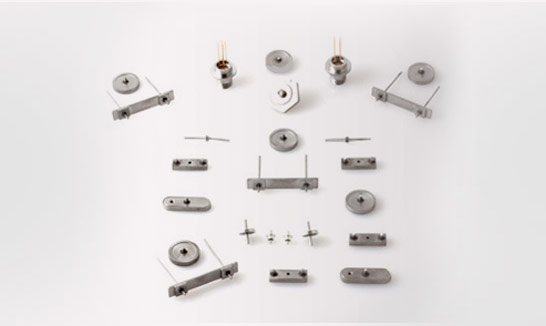

Complete Hermetics is a trusted custom manufacturer of glass-to-metal, ceramic-to-metal, hermetic seals, and hermetic feedthroughs. We bring decades of technical expertise to help you design and develop the perfect hermetic connectors, hermetic packages, hermetic headers, vacuum viewports, and more—each solution tailored to your application.

Whether your project requires prototyping or full-scale production, we deliver the quality, performance, and customization you need. Let us help you keep your systems protected and fully operational—anywhere in the world.

📞 Phone: 714-265-1238

📧 Email: info@completehermetics.com

🔗 Contact Form: https://www.completehermetics.com/contact-us/

🌐 Website: www.completehermetics.com

Explore solutions with Complete Hermetics—the leader in defense hermetic feedthroughs and sealing innovation.