Why Lithium Battery Sealing Is Critical

Lithium battery seals are crucial for preventing gas leaks, moisture ingress, and electrical shorting in energy-dense power systems. With the growth of electric vehicles, medical implants, and aerospace devices, the need for reliable sealing has never been greater. A well-engineered seal ensures long-term stability, safety, and optimal performance, protecting both the battery’s internal components and the end application it powers.

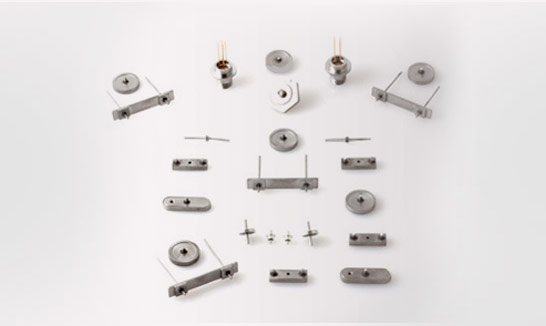

Advanced Glass-to-Metal Sealing Technology

Complete Hermetics produces battery end seals and glass-to-metal lids capable of withstanding extreme temperature swings from –40 °C to +150 °C. These seals resist electrochemical corrosion, vibration, and internal pressure fluctuations—ensuring both safety and performance over time.

Applications Across Industries

Battery end feedthrough seals from Complete Hermetics are used in:

- Medical and healthcare equipment

- Communication and monitoring systems

- Electric and hybrid vehicles

- Aerospace and defense power sources

Testing and Quality Assurance

Each seal undergoes a leak-rate test of 1 × 10⁻⁸ cc He/sec and insulation checks to ensure air-tight integrity. Optional plating in nickel, gold, or tin enhances corrosion resistance and solderability.

Engineering Support and Customization

The engineering team collaborates with clients to design custom geometries, feedthrough pin counts, and housing materials to meet specific energy-density and thermal-expansion needs. This collaborative approach ensures every hermetic connector is optimized for performance, reliability, and seamless integration into the client’s system.

Contact Complete Hermetics Today

For reliable lithium battery seals, battery feedthroughs, and glass-to-metal lids built for safety, performance, and endurance, parther with Complete Hermetics today.

Contact Info:

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com