The Advantage of Ceramic-to-Metal Technology

When environments exceed the limits of glass, ceramic-to-metal seals become the gold standard for thermal and electrical isolation. These seals are engineered to withstand extreme temperatures, voltages, and vacuum pressures without degradation—making them indispensable in aerospace propulsion, particle physics, and medical imaging systems.

High-Performance Applications

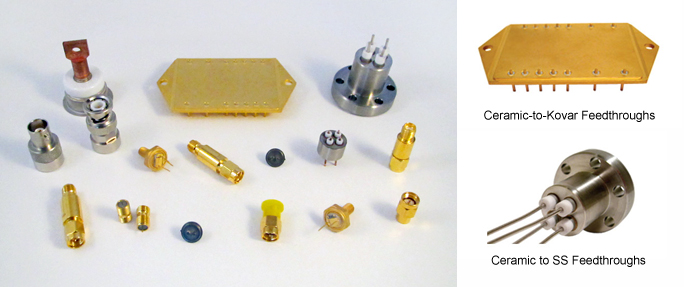

Ceramic-to-metal feedthroughs are used in high-voltage power transmission, RF systems, X-ray machines, and vacuum processing chambers. Their excellent dielectric strength ensures signal stability while maintaining full hermetic integrity.

Engineering and Design Excellence

Complete Hermetics produces custom ceramic-to-metal seals using alumina ceramics bonded to stainless steel, Kovar, or titanium through metallization and brazing. Each joint undergoes ultrasonic inspection, helium testing, and dimensional analysis to confirm long-term sealing reliability.

Benefits Over Traditional Glass Seals

Compared with glass, ceramics provide higher breakdown voltage, improved heat resistance, and lower leakage. This makes them ideal for applications exceeding 500 °C or operating under continuous voltage loads.

Collaborative Development Process

From prototype to production, Complete Hermetics works directly with customers to optimize designs for performance, manufacturability, and cost efficiency. Engineers can tailor electrode geometry, pin diameter, and insulation thickness to meet exact system needs.

Contact Complete Hermetics

Choose Complete Hermetics for high-reliability ceramic-to-metal seals and feedthroughs proven in extreme operating environments.

Contact Info:

- Contact Form: https://www.completehermetics.com/contact-us/

- Phone: 714-265-1238

- Email: info@completehermetics.com