Hermetically sealed connectors are essential components in applications where machinery and equipment are exposed to extreme conditions. From aerospace to medical industries, these specialized connectors ensure airtight protection, making them indispensable for sensitive electronic systems. Their robust design prevents the ingress of gases, moisture, and contaminants, safeguarding equipment functionality in harsh environments.

What Are Hermetically Sealed Connectors?

Hermetically sealed connectors are engineered to provide a secure, vacuum-tight seal between systems. They are commonly used in environments that experience extreme weather, fluctuating atmospheric pressure, and high altitudes. For instance, photographic and surveillance equipment on unmanned vehicles rely on hermetic seal products to maintain airtight integrity. These connectors are also critical in submarines and satellites, where they resist significant pressure differences while ensuring no moisture or gases compromise system performance.

Reliable Moisture and Gas Protection

One of the primary advantages of hermetic connectors is their ability to act as a robust barrier against moisture and gas penetration. When high-pressure differential barriers are necessary for electrical systems, poorly constructed seals can lead to malfunctions. Hermetically sealed connectors effectively mitigate these risks, providing long-term resistance to corrosion and ensuring system reliability. This is why industries like automotive, offshore drilling, and defense frequently use custom hermetic connectors tailored for their unique requirements.

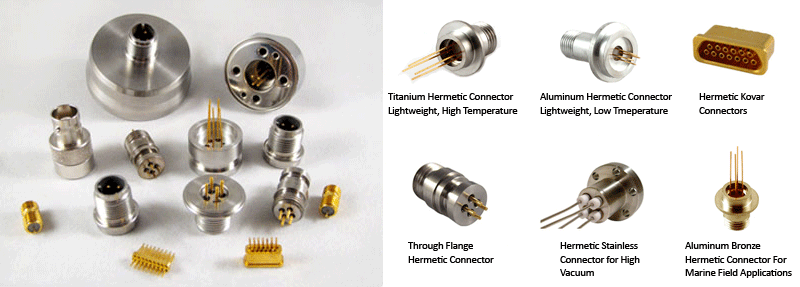

Circular and Rectangular Connectors for Versatile Applications

Hermetically sealed connectors come in various configurations, including circular and rectangular designs, to accommodate different systems. Circular connectors are often preferred for their compact and durable build, making them ideal for aerospace and military applications. On the other hand, rectangular connectors offer versatility for larger-scale systems in manufacturing plants and laboratory equipment.

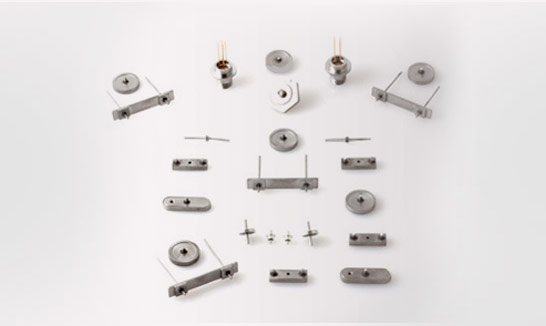

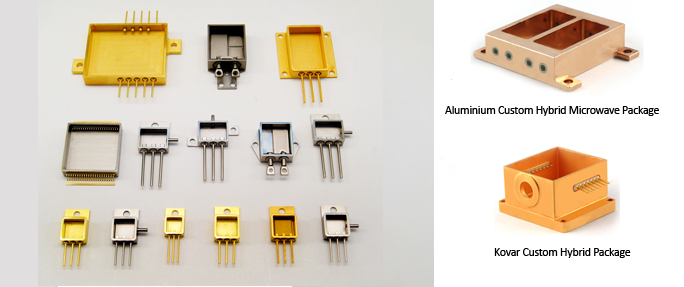

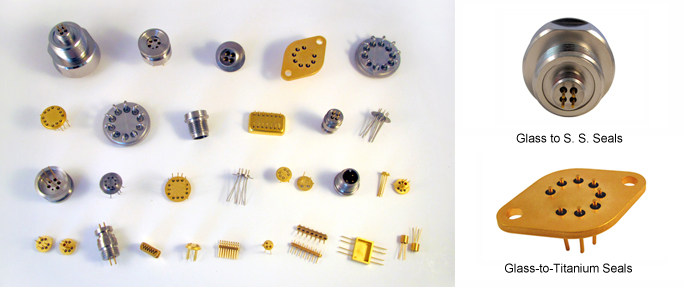

Custom Hermetic Connectors by Complete Hermetics

For high-performance hermetic sealing solutions, Complete Hermetics stands as a trusted provider. Their custom hermetic connectors are designed to meet specific mounting requirements, ensuring compatibility with diverse industrial applications. Whether you need connectors for vacuum chambers, submarines, offshore rigs, or medical devices, Complete Hermetics delivers precision-engineered solutions.

Choose Complete Hermetics for unparalleled expertise in hermetic seal products and connectors that protect critical systems from environmental challenges.