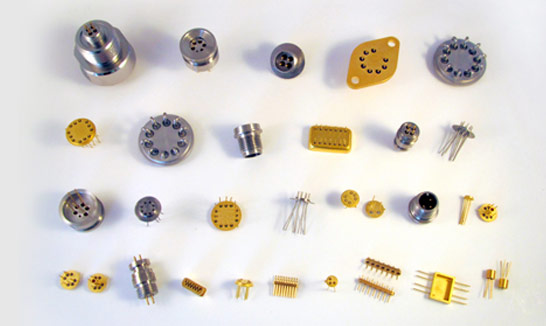

Complete Hermetics is a custom prototype designer and manufacturer of hermetic seals and hermetic feedthroughs. Complete Hermetics offers a complete line of glass-to-metal seals and electrical feedthroughs to meet every type of need.

Complete Hermetics specializes in glass-to-metal and ceramic-to-metal sealing and electrical feedthroughs that are suitable for a variety of applications. Complete Hermetics manufactures hermetic feedthroughs as well as high-voltage applications and vacuum feedthrough capabilities. Complete Hermetics will custom build any seal or feedthrough according to the customer’s specifications.

Complete Hermetics Offers Complete Glass-To-Metal Seals and Feedthroughs

Complete Hermetics uses industry standards to create reliable glass-to-metal feedthroughs and seals according to the following system:

- Glass is heated to a molten state then wetted to the metal, forming a tight bond.

- The thermal expansion of the glass and the metal are carefully measured and controlled to prevent breakage.

Complete Hermetics offers many options for feedthrus types and standard. Complete Hermetics offers not only electrical feedthroughs, the most common type we make, but also RF and microwave feedthroughs.

Complete Hermetics glass-to-metal seals are very effective in sealing hermetically during severe temperature changes as well as sudden changes in pressure or humidity. Although moderately effective sealing may be produced with simple epoxy potting, fused glass-to-metal seals are usually specified in high-pressure and high-temperature applications. Glass is an excellent insulator and bonds well to metallic surfaces and is extremely corrosion resistant. Glass seals are also very cost-effective when compared to ceramic seals and may be used in a wider variety of applications. Therefore, Complete Hermetics offers a complete line of glass seal products for a wide variety of uses.

The pin and body assemblies of Complete Hermetics glass-to-metal seals and feedthroughs can be plated for better corrosion resistance, wire bonding and soldering capabilities. Plating options include gold, silver, electrolytic and electroless Ni and tin.

Complete Hermetics also specializes in hermetic seals of titanium terminals, headers and hermetic connectors for medical equipment such as titanium batteries, diagnostic equipment and sensors.

Our experienced engineers will help you with layout and cna recommend sizes, solders and other specifics about your hermetic seals and feedthroughs.

There are two types of glass-to-metal seals; compression seals, in which the materials used have different coefficients of thermal expansion, and matched seals, in which the two materials have similar CTEs

Compression Seals

Compression (mismatched) seals are created when the CTE, coefficient of thermal expansion and contraction, of the header body or housing greatly exceeds that of the glass or electrodes. During the firing process, the metal materials, usually stainless steel, expand at a great rate than glass. During cooling, the metal contracts into the already solidifying glass to form an extremely robust compression bond. This type of seal is frequently specified for extreme high pressure applications. The working pressure can be as high as 14,000 PSI range. Materials used by Complete Hermetics can include:

- Body Materials: Cold rolled steels, Stainless steel, Inconel, etc.

- Glass Materials: Corning 9010/9013 (Alkali Barium), Soda lime, Lead silicate, etc.

- Electrodes Material: Alloy 52, Copper Cored 52 Alloy, Alloy 42, etc.

Typically Compression Seals withstand temperatures ranging from -250°C to 400°C. Allowable operating temperatures would be from -60°C to 200°C under thermal cycling and shock.

Matched Seals

When the CTE (Coefficient of thermal expansion) of the body or housing material matches are very relatively close, usually within 10% of each other. This results in a product in which the stress in the glass is relatively small. See note. This is extremely important in glass hermetic connectors such as the micro-d because of the rectangular shape of the shell. Matched seals can withstand high thermal and mechanical shock and are easier to manufacture compression hermetic seals. The hermetic seal is made by forming a bond through wetting and chemical reactions between the glass and metal. Kovar is the most commonly used material for matched seals.

- Body Materials: Kovar, Alloy 42, Tungsten, Molybdneum

- Glass Materials: Corning 7056 (Alkali Borosilicate)

- Electrodes Material: Kovar, Alloy 42, Tungsten, Molybdneum

Typically Matched Seals maximum allowed temperature is limited by the glass material strain point. Matched seals can withstand high thermal and mechanical shock and are easier to manufacture than compression hermetic seals.

Properties of Hermetic Glass-to-metal Seals

The following properties are part of the glass-tometal seals and feedthroughs and are standards for Complete Hermetics products.

Hermetic seal properties:

- Hermeticity: up to 1 x 10-9 atm cc/sec He

- Insulation resistance: typically exceeds 1 GΩ @ 100 VDC

- Mechanical strength can withstand 20,000 psi with proper design for use in high-pressure applications

- Dielectric: can withstand voltage depending on joint geometry and glass material selected. Below are some typical glass values

– Barium Alkali: 6.3

– Brososilicate: 4.9

– Soda Lime: 7.2

Plating and Finishes

Pin and body assemblies can be plated for better corrosion resistance, wire bonding and soldering abilities.

Plating Options

• Gold Plating

• Silver Plating

• Electrolytic and Electroless Ni Plating

• Tin Plating

Ceramic-Doped Glass

Complete Hermetics has designed a new process to create high-reliability ceramic glass seals. These feedthrough seals are appropriate for use in hermetic terminals, hermetic connectors and hermetic packages, Depending on the thermal cycle, conventional seals can withstand about 300°C, but these new ceramic seals are rated to withstand temperatures up to 600°C. This ceramic-doped glass process can fabricate seals at a substantially lower cost than the ceramic-to-metal feedthrough process.

For more information on ceramic-to-metal seals and feedthroughs.