Ceramic to metal brazing are commonly found in electrical feedthrus, laser devices and microwave tubes, etc. Due to their good performance for high vacuum, high voltage and high pressure applications, medical and military devices have more and more demands in recently years for their biocompatibility and high joint strength.

Process Service & Prototype Development

- Vacuum Brazing

- Active Metal Brazing

- Hydrogen Brazing

- Reactive Air Brazing

- Ceramic Metallization

- Modeling and Simulation

- Fixture Tooling Design

- Stress/Reliability/Failure Analysis (Modeling and Characteristics)

Metallization Process on Ceramic Glass, etc.

- Mo/Mn (Thick Film)

- Sputtering or Vacuum Evaporation (Thin Film)

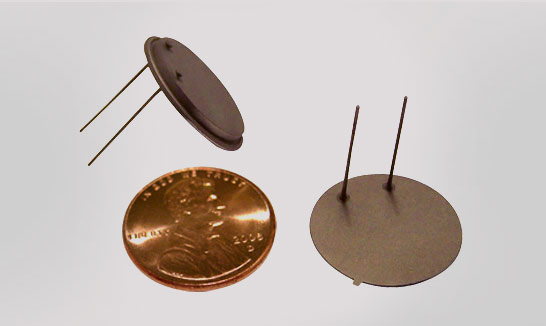

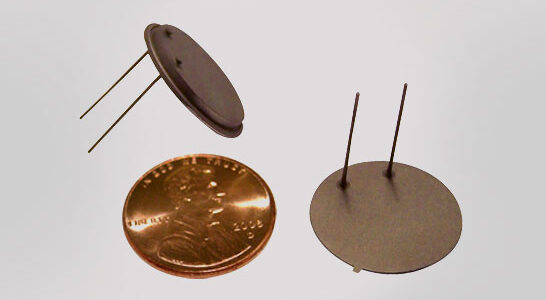

Ceramic to Metal Brazing & Soldering

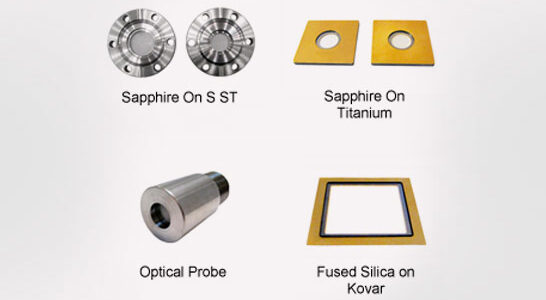

Typical Ceramics for Brazing & Soldering

- AlN, BeO, Si3N4, SiC, AlSiC, BN, ZrO2, YSZ, YAG

- Polycrystalline Alumina (94%-99%)

- Graphite

- Ruby

- Sapphire (100% Alumina)

Typical Braze Alloys

- Gold and its Alloys

- Silver and its Alloys

- Copper and its Alloys

- Other

Typical Metals/Alloys for Brazing/Soldering

- Molybdenum

- Niobium

- Kovar

- Invar

- Titanium

- Inconel

- Nickel, Ni Alloys (Monel, Alumel) and Super Alloys

- NiFe Alloys

- 300 Series SST (304, 316, 321) and Inconels

- 400 Series SST (410, 430)

- NiTi and Other Alloys